For more than 20 years, Johannes Spatz has held management positions at Panasonic in Germany and Europe. In an interview with J-BIG authors Björn Eichstädt and Nina Blagojevic, the Managing Director of Panasonic Industry Europe shares how he positions the company’s business in Germany and Europe, how the Panasonic brand operates as a whole, and how COVID-19 has changed internal collaboration between Germany and Japan.

J-BIG: Mr. Spatz, it is probably safe to say that all readers know the name Panasonic, but not everyone might be familiar with Panasonic Industry Europe. What is the relationship between the two companies?

Johannes Spatz: Here in Germany, Panasonic is primarily known for our consumer audio-visual systems – televisions, cameras and so on. This is still a central business field, especially when it comes to branding. But there are also four other business areas – we call them „companies“ internally – which are less universally known: „Life Solutions“, „Automotive“, „Business“ and „Industrial Solutions“.

Panasonic Industry Europe is part of the Industrial Solutions segment. Our product portfolio is very broad and ranges from small electronic components such as resistors or capacitors to modules and partial solutions. In factory automation in particular, Panasonic Industry often produces subsystems like controllers, laser marking systems or motors for industrial applications on the factory floor.

Life Solutions covers everything from prefabricated houses to toilets and special roof tiles made from plastic – you can build almost an entire house from Panasonic products. Automotive, as the name suggests, is concerned with the automotive industry, traditionally in the form of convenience electronics. And the Business segment is mostly focused on factory automation, as well as infotainment systems for the aviation industry, which unfortunately is under a lot of pressure at the moment. Panasonic is the market leader in this area, with a market share of well over 50 percent. If you‘re watching a movie on a long-haul flight, you‘re very likely doing it on a Panasonic system.

J-BIG: What is the role of Panasonic Industry Europe?

Johannes Spatz: Per definition, we are a sales organization, charged with selling the Group‘s products throughout Europe. The European headquarter here in Ottobrunn near Munich consolidates these activities.

My ambitions, however, go beyond that – our goal is to create added value for the customer by offering not just products, but individual customer solutions from different business areas. In the end, our customers are not interested in whether a product belongs to Automotive, Life Solutions or Business. For them, it‘s all Panasonic – and they want a single point of contact for all relevant products and solutions.

One of our most important activities is therefore to bring together on the customer side what must remain separate in organizational terms. That‘s why we also look at technologies or products from other business areas and try to find new industrial applications for them. The best example here is solar cells: They actually belong with the Life Solutions sector and are not sold on a large scale in Europe, but they are nevertheless of great interest for specific applications.

J-BIG: What are your target markets, and how do they differ in Germany and Japan?

Johannes Spatz: We don‘t focus on very narrow target markets. Rather, we want to cover as broad a spectrum as possible with the breadth of our product portfolio. In this, we distinguish between three major areas: Living, Mobility and Business. We all spend most of the day either at home, at work, or on the go, after all, so these three cover a lot of ground.

The strategic differences between Japan and Germany are mostly about how we approach these categories. The Living area is a good example: Panasonic‘ s Life Solutions products are very strongly focused on the domestic Japanese market: Panasonic brand razors and bicycles are ubiquitous there, but you will hardly find them in Germany. This does not mean, however, that this area is not also relevant for us from a supplier perspective – Panasonic Industry Europe provides batteries and components for Braun, Philips and Co.

The same is true for the mobility sector: Panasonic Industry Europe does not build any vehicles or engines. But as a Tier 2 manufacturer, we equip the major suppliers – Bosch, Continental, Valeo, ZF, all the big Tier 1 companies. So our strategy in Europe and Germany is to go broad on a lower level of the value chain. As a result, Panasonic Industry Europe might be less visible to the end consumer, but it is hidden in many German products. We use the hashtag #weareIN in our communication to express this. As Panasonic Industry, we

“We can contribute our expertise wherever electronics are involved.”

J-BIG: What future prospects do you see for Panasonic Industry Europe, especially in the German market?

Johannes Spatz: We are thinking in different directions here – basically, we can contribute our expertise wherever electronics are involved. In the automotive industry, for example, electrification is an important driver for us. In combustion engine cars, we are mainly involved with convenience electronics, but electromobility for the first time gives us the opportunity to advance into the heart of the car: the drive train. Our batteries, high-power relays or DC link capacitors can already be found in everything from a Tesla to Nissan’s and BMW‘s electric models. And we still see a lot of future potential here, especially in Europe and Germany.

We are also positioning our technologies in the broader e-mobility environment. For example, we have set up a new Cycle-Tech division which, among other things, offers engines for e-bikes. And we are working on air mobility with several research projects, for example in cooperation with Airbus.

The topic of infrastructure more generally is becoming increasingly important in this context. For instance, we also supply components for charging stations and charging cables. Every charging system must be switched on and off. That sounds simple enough, but in the event of a short circuit, hundreds of amperes and thousands of watts are involved – not every relay is able to handle that. At the same time, we are already active in the growing field of data infrastructure: our electronics ensure an uninterrupted power supply for the European data centers of Facebook and Amazon, for example.

Energy infrastructure solutions for buildings are also conceivable in the future. Together with a partner, we have just equipped our entire roof in Ottobrunn with Panasonic photovoltaic modules. The cells come from us, and we already manufacture infrastructure components like energy meters. Several other companies have noted this development with a lot of interest.

Free Subscription

“J-BIG – Japan Business in Germany” is the e-mail magazine dedicated to Japanese companies and their business activities in the German market.

J-BIG: You have been the CEO of Panasonic in Europe since 2004 – a remarkable success. Do you have any advice for German managers who want to advance in Japanese companies?

Johannes Spatz: The most important thing is to engage in a cultural change of perspective. In German companies, much revolves around facts and evidence: How do I arrive at the right solution? Who’s opinion is correct? In Japanese companies, the more important questions often are: How do others see this issue? What do we have to do to find a consensus? This is not to say that facts are not important to the Japanese. On the contrary, our products are often concerned with every millimeter. But in the spirit of Nemawashi, it is essential to gather different opinions and to bring all divisions on board in order to reach a decision. This can drive German employees crazy – they might end up impatiently repeating all the facts again, which in turn drives their Japanese colleagues up the wall. Especially when dealing with headquarters, you simply have to embrace this approach and respect the processes.

My advice to everyone traveling to Japan on business for the first time is simple: behave as you would as a guest in any new environment. Be polite, perhaps a bit restrained, observe, do not try to make yourself the center of attention. In my experience, this kind of behavior will be appreciated and rewarded.

There is, however, one exception when it comes to restraint: Nomikai, the after-work drink. This is a chance to get more closely acquainted in a relaxed atmosphere. Often, it will help reach a consensus almost automatically, which is a very important common ground for future collaboration. It only happened twice in my career that a Japanese man – completely sober, I might add – threw his arms around me. That’s the result of a bond of trust that has been slowly built up over many years.

J-BIG: How has the COVID-19 situation changed the cooperation with Japan?

Johannes Spatz: First of all, I was very surprised at how quickly Japan reacted here. Not so long ago, home office was still unthinkable, but from what I hear, it is really being implemented consistently now.

Secondly, we all noticed that digital technology can compensate a lot of things, or even make them easier. We had been trying to implement Microsoft Teams for years, and suddenly it happened over one weekend – when we came into the office on Monday, everything was already up and running smoothly. So instead of flying to Japan for a two-hour reporting meeting, I can now simply do it virtually.

On the technical side of things, everything is therefore running smoothly, but something is still undoubtedly lost. We have less insight into the informal negotiations and processes that are happening in Japan. Even our Japanese expats struggle with this to some extent. And on the flipside, it is just as important that Japanese colleagues come to Germany, experience Europe, meet the customer on site, and so forth. There is no virtual substitute for that. So while my goal for the future is to reduce travel, we definitely can‘t do without it completely.

J-BIG: How much of the Japanese Panasonic culture is also part of Panasonic Industry Europe?

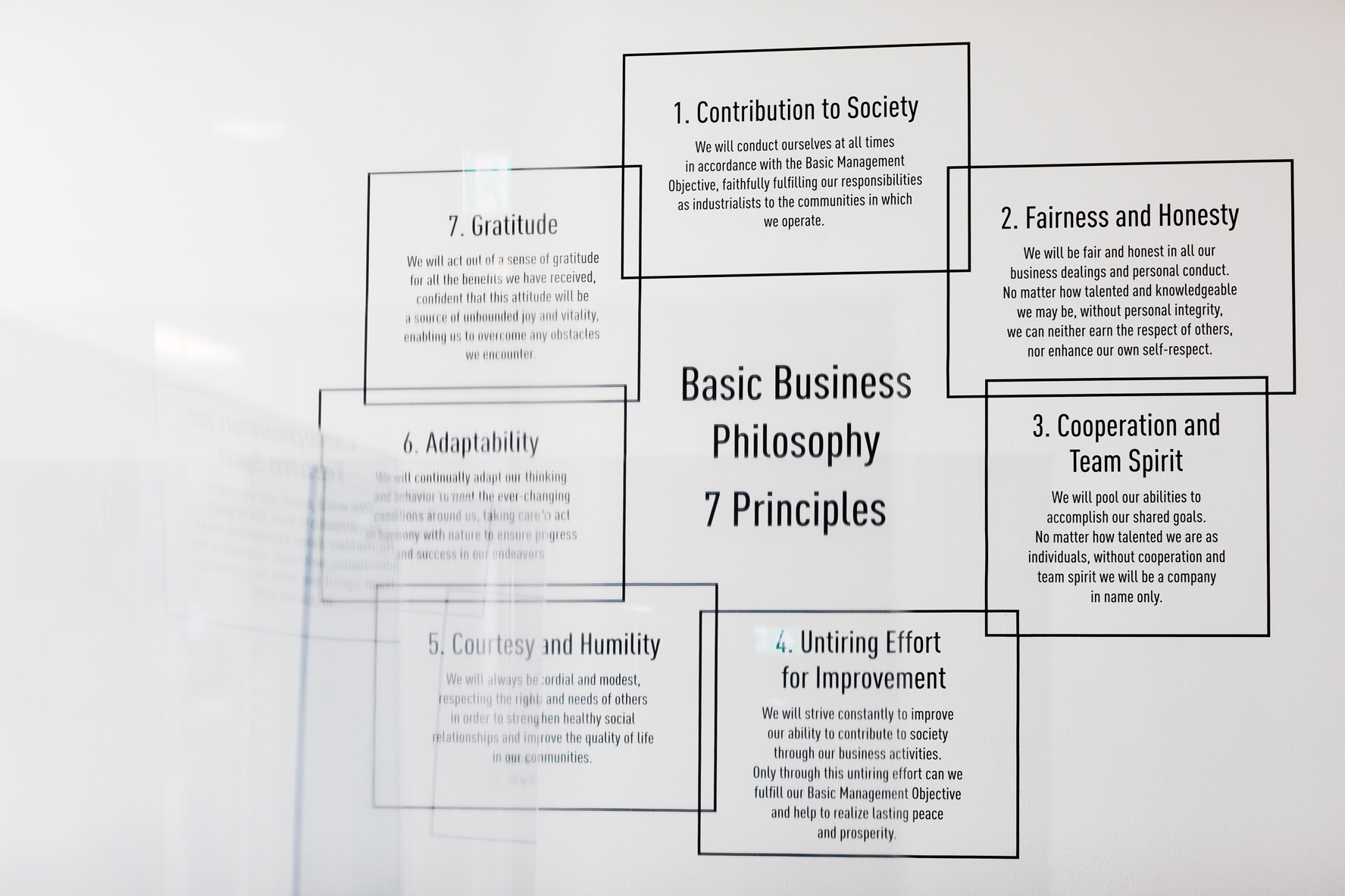

Johannes Spatz: Our corporate culture is definitely shaped by the Japanese company history. The principles and values formulated by Konosuke Matsushita, the founder of Panasonic, in 1932 are still valid today – and they are lived globally. Even if structures or workflows differ to some extent, these values are a common ground and facilitate international cooperation. No matter how many things we disagree on, who we are or what is important to us is never up for debate.

J-BIG: Panasonic Industry Europe illustrates that Japanese companies can be successful in Germany. Would you also advise other Japanese companies to take the step into the German market?

Johannes Spatz: That somewhat depends on the industry – if you are looking to gain a foothold in the European automotive industry, for example, Germany is certainly a good place to be. But beyond that, recent developments are also reaffirming Europe, and Germany in particular, as attractive business locations. The COVID-19 pandemic has to some extent revealed the limits of globalization; as a consequence, localization will gain importance once more. Simple supply chains, fast response times, agility – all of these require proximity to the customer. I am convinced that individual production and the whole topic of „customization“ will have a greater impact on the markets in the future. And with its strong small and medium enterprise (SME) sector, Germany is still well equipped to meet this challenge. So anyone wanting to pursue this trend in Europe would do well to come to Germany.